In the ever-evolving world of 3D printing, speed is a sought-after attribute that can significantly impact efficiency and productivity. Enter the realm of the fastest 3D printers – machines that push the boundaries of rapid prototyping and manufacturing. In this article, we delve into the cutting-edge technology, design principles, and applications that make these speed demons a game-changer in the world of additive manufacturing.

The Need for Speed in 3D Printing

Time is of the essence in industries ranging from aerospace and automotive to healthcare and consumer goods. The faster a 3D printer can fabricate intricate parts or complex designs, the quicker products can reach the market, prototypes can be tested, and custom parts can be manufactured.

Breakneck Speed: How Do They Do It?

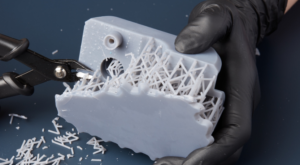

1. *Innovative Extrusion Mechanisms:* Some of the fastest 3D printers utilize advanced extrusion systems that efficiently deposit layers of material. These systems ensure smooth and precise material flow, contributing to quicker print times.

2. *Parallel Printing:* Certain printers are equipped with multiple print heads or printheads with multiple nozzles. This allows them to print multiple parts simultaneously, slashing the time required to complete a batch of parts.

3. *High-Speed Motors and Mechanics:* The mechanical components of a 3D printer play a vital role in its speed. Fast 3D printers employ high-speed motors, precision linear rails, and optimized mechanics to minimize print head movements and maximize printing efficiency.

4. *Advanced Materials and Hotends:* Fast printing requires materials that can be extruded quickly without compromising quality. High-speed hotends can achieve the necessary melt rates, ensuring consistent and rapid material deposition.

Applications and Industries

The speed advantage of these printers opens up a plethora of applications across various industries:

1. *Prototyping and Product Development:* Rapid iteration and testing of prototypes are crucial for product development. Fast 3D printers allow designers and engineers to create and assess models in a fraction of the time.

2. *Medical and Healthcare:* From customized medical implants to anatomical models, the medical field benefits from accelerated printing when every moment counts.

3. *Aerospace and Automotive:* Production of lightweight parts and components used in aerospace and automotive industries can be expedited, enabling faster innovation and reducing downtime.

4. *Consumer Goods and Electronics:* Quick production of consumer goods and electronic components meets the demands of the fast-paced consumer market.

Conclusion

As technology advances, the race to achieve faster 3D printing speeds continues to shape the landscape of additive manufacturing. These high-speed 3D printers are transforming industries by providing unparalleled efficiency, enabling rapid prototyping, and streamlining production processes. However, it’s important to note that while speed is a remarkable feature, a balance must be maintained with print quality and precision. With further innovation, we can anticipate even more astonishing feats from these speed demons, opening new frontiers for creativity and manufacturing.

Experience the convenience of online 3D printing services, where you can easily upload your designs, select materials, and have your custom creations delivered right to your doorstep.